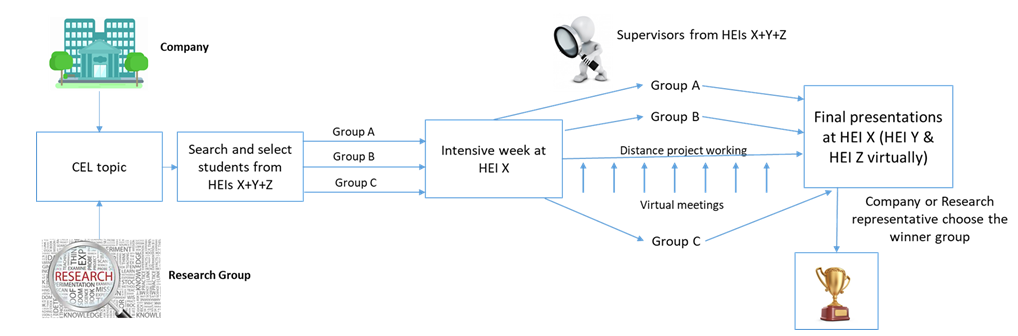

CEL Projects focuses on bringing students, HEI staff and company experts to work together. The idea is that students from different study programs and nationalities are brought together to form mixed groups in order to solve a industry or research topic.

Description: During implementation of a CEL project, three groups of students compete in solving the proposed topic over one academic semester. Their work is supervised by teachers from participant universities and representatives from the company or research groups.

The work on problem solving involves one intensive week at the start of the project and distance working and virtual meetings during the semester. At the end of the project virtual seminars are organized where the three student groups present their results to the company/research group. Read more : CEL Projects Brochure.

1st Round of CEL Projects

In the first Round of CEL Projects, three such projects are implemented. The projects implementation period is associated with the spring semester in each of the 3 partner HEIs. The intensive week is organized during week 7 (12-16 Feb 2024). The selected topics for the three projects are:

CEL1 – ISR

Topic: Design of an olive quality control system

Objective: Design and develop a station (machine vision system) able to classify the olive quality based on multispectral and or hyperspectral images of olive fruits.

CEL2 – TUCN

Topic: Design of a 3-axes GANTRY ROBOT (3GR)

Objective: Design a 3-axes GANTRY ROBOT subject to the following requirements: – the movement along the X, Y, Z axes is carried out using electric motors mounted on the fixed base of the robot (they must not be mounted on moving parts); the transmission of the movement for the axes (X, Y, Z) is done using toothed belts; the robot workspace is 300 x 400 x 200 mm3 (X, Y, Z)

CEL3 – Valmet

Topic: Design of a test object for a pressing-based manufacturing process

Objective: Conceptualizing and designing a “test object” for a pressing-based manufacturing process. The knowledge from such tests can be used to adjust process parameters and mechanics for totally new concept of pressing wood-based materials

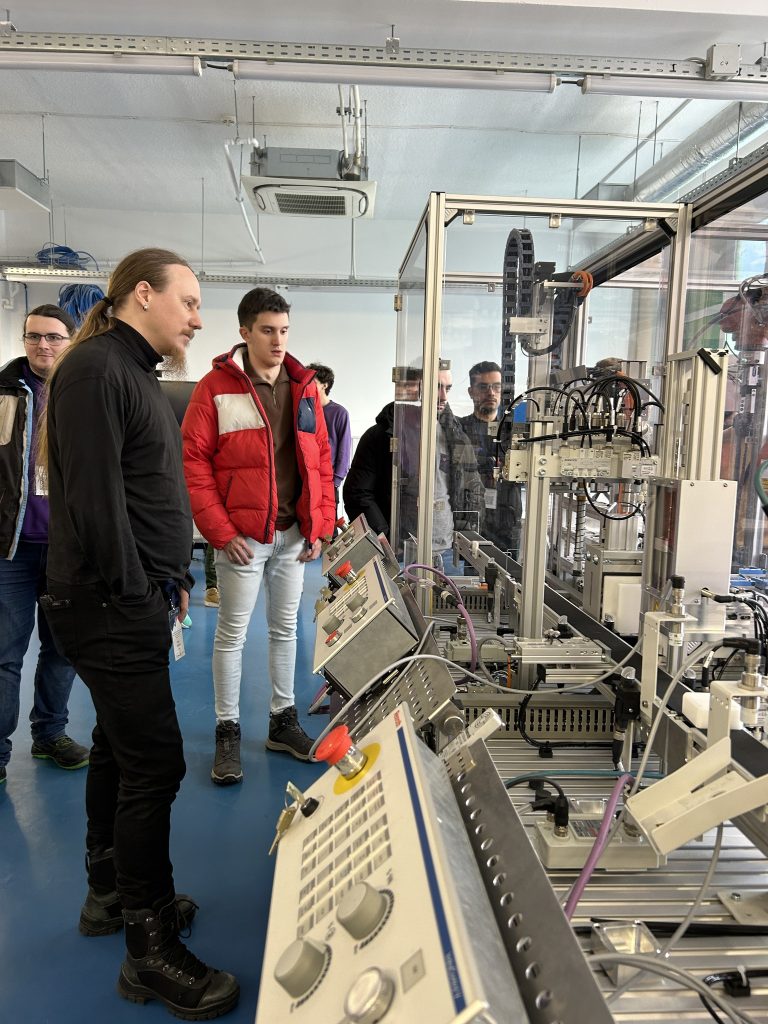

Each of the three CEL Projects start with an intensive week organized by the hosting HEI in each of the three EU countries. During the intensive week all participant students have the opportunity to meet, organize the teams, interact with company and research groups experts on the proposed topics, participate in tailored lectures and social activities. The agenda of the first round intensive weeks are:

ISR CEL Project

TUCN CEL Project

VALMET CEL Project

The students’ final presentations in the 1st CEL Project Round were organized for all three projects at the end of April 2024. The meetings were organized online using MS Teams. During the event, each student team presented their results to the supervisors and company/research group representatives. Based on the students’ reports and presentations a winning team was selected for each of the three projects.

2nd Round of CEL Projects

The second round of CEL Projects includes 3 three such projects. The implementation period of the project is in the Spring semester of the 2024-2025 academic year. All three projects will start with an intensive week during organized in week 7 (11-15 Feb 2025). The selected topics for the second round are:

CEL4 – Bosch

Topic: Evaluation of the screws tightening and elongation in PCB mounting operations

Objective: Identify the optimal tightening range and elongation of M6 screws in PCB mounting across various housings. Analyze the situations where the screw fractures, while final tightening torque is not reached and inside of the given angle tolerance.

CEL5 – JAMK & Valmet

Topic: Automatic or semi-automatic cleaning to be developed for the blade change device

Objective: Conceptualizing and designing a “cleaning ability” for a blade changing device. Device is manufactured by 3D printing. The removal of waste generated by the cleaning process must also be planned.

CEL 6 – UJA

Topic: Products redesign via Additive Manufacturing

Objective: Jet engine combustion chamber mockup redesigned aided by additive manufacturing. Reverse engineering to obtain the chamber’s main dimensions. -3D model redesign based on AM: proposed demonstrator with fewer components. -Numerical simulation of flow lines through the demonstrator

In the second round, the three CEL projects kick off with an intensive week from February 11–14, 2025. During this period, students will form teams, engage with industry and research group experts, and start developing solutions for the assigned topics.

Boch Cluj Plant CEL Project

Jamk & Valmet CEL Project

UJA CEL Project

The final student presentations for the 2nd CEL Project Round took place in the first part of April 2025, covering all three projects. The sessions were held online via MS Teams. During the event, each student team showcased their results to the supervisors and representatives from the partner companies and research groups. Based on the submitted reports and presentations, a winning team was selected for each project.